What is a Prepreg?

A Prepreg is an industry term used for a reinforcing fabric, such as carbon fiber or fiberglass, that has been pre-impregnated with a resin system. The resin system used to impregnate the material contains the proper resin and hardener mixture to facilitate curing – making prepregs ready to layup without additional resin work required.

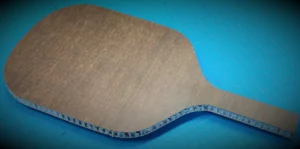

Generally, prepregs are used by fabricators to produce parts requiring lightweight, consistent, high-quality result thought-out various industries including aerospace, medical, space, automotive, racing, sporting goods and more.

TYPES OF PREPREGS

Most often, the resin used to impregnate a fabric is an epoxy resin, but other types of resin can be used including a variety of thermoset and thermoplastic resins. Though they both are considered a prepreg, the two types are dramatically different.

Thermoset Prepregs

With a thermoset prepreg, the thermosetting resin starts as a liquid and fully impregnates the fiber reinforcement. Excess resin is precisely removed and then undergoes a partial curing. The state of the resin changes from a liquid to a solid. This is known as “B-stage.”

In the B-stage, since the resin is partially cured and usually tacky, it requires cold storage to prevent it from fully curing. When heated, a prepreg often returns briefly to a liquid state prior to hardening completely. Hence, composite structures built of prepregs will usually require an oven or autoclave to finish the complete polymerization. In addition, once a thermoset prepreg is formed, it cannot be remolded or reshaped.

Thermoplastic Prepregs

Thermoplastic resins are extremely common and are often unreinforced. Fabrics that are impregnated with a thermoplastic resin are stable at room temperature and, generally, do not have a shelf life. When at room temperature they are at a solid state. When heat and pressure are applied, a thermoplastic prepreg will often can be reformed and reshaped.

Unreinforced resin means the resin is formed into shapes but has no reinforcement providing strengthAs we continue to learn more about prepregs, keeping in mind that we are referring thermoset prepregs.

ADVANTAGES OF PREPREGS

Using prepregs are becoming increasingly common in the composite industry due to advantages including their strength properties, ease of use, consistent part production, and high-quality surface finish.

- Controlled Resin Content

- With the process of impregnation, the fabric-to-resin ratio is easily controlled because the desired amount for both resin and hardener already impregnated directly into the fabric. Most prepregs contain 30-35% resin content which is ideal for achieving maximum cured resin properties.

- Part Uniformity

- Products manufactured with prepregs show to have reduced problems with varying thickness, excess weight and inconsistent finish that occur with hand layups. Controlled resin content helps produce consistent parts and takes the worry out of having resin rich areas, dry spots or air bubbles in the finished product. Mold preparation and handling techniques can still affect the final product, but uniformity and repeatability are more easily attainable with the use of prepregs.

- No Hand Layups

- Using a prepreg eliminates the need for hand mixing resin and hardener. Most epoxy hardeners are considered hazardous and dealing with resins in a liquid state can be messy. A prepreg comes with the desired amount for both resin and hardener already impregnated in the fabric. This helps produce consistent parts and takes the worry out of inaccurate measuring, excess resin weight and resin voids in the finished product.

- No hand layups also reduces the mess and waste that comes with mixing resin. No more need for cups of resin, accurate part measuring and mixing supplies. Since prepregs can be handled at room temperature, there is no fighting the clock trying to avoid your resin setting up before you are ready.

- Less Curing Time

- No more waiting for your part to finish its cure cycle. Once the heat curing cycle is completed, the part is finished. You do not have to wait the standard 24-48 hours to allow a full cure, as in typical hand layups.

DISADVANTAGES OF PREPREGS

As great as prepregs are, there are some disadvantages to consider including cost, shelf life and curing requirements.

- Cost

- Using prepregs can be cost prohibitive. The additional step of impregnating a fabric adds increased cost and, in some instances, can double the material cost. Even when you add up the cost of the resin, hardener and fabric- prepregs still cost more.

- Heat Curing

- Prepregs usually require a combination of heat and pressure to facilitate curing. Many manufacturers use an oven or autoclave to cure prepregs. You must be able to achieve a minimum of 270°F and maintain that temperature for a minimum of 4 hours.

- Shelf Life & Storage

- Most commonly used prepregs are impregnated and partially cured. Often, they require refrigeration or freezing prior to use, adding additional transportation and storage cost. The shelf life of prepreg is significantly affected by the temperature at which its stored. In comparison, prepregs tend to have an overall shorter shelf life than dry fabric.

USING PREPREGS

Prepregs will arrive either via frozen truck or shipped overnight packed in dry ice. Depending on the method, the material may have begun to thaw so though not required, it is highly recommended to place the material in a freezer upon its arrival.

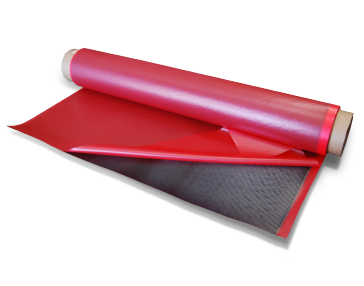

When ready to begin working with a prereg, the material must be given time to slowly thaw. A thawed prepreg is tacky because the resin is partially cured. So, to prevent the material from sticking together, it is sandwiched between two backing sheets that can easily be peeled away when ready to layup the material.

Due to the tackiness of the prepreg at this stage, the prepreg material must be placed carefully because it cannot be repositioned. When in the B-Stage the prepreg can easily be handled, trimmed, pleated and formed using a composite shears. After the part is laid up, it will need to undergo vacuum bagging to compress the layers of prepreg and reduce air pockets and remove any excess resin.

Due to the tackiness of the prepreg at this stage, the prepreg material must be placed carefully because it cannot be repositioned. When in the B-Stage the prepreg can easily be handled, trimmed, pleated and formed using a composite shears. After the part is laid up, it will need to undergo vacuum bagging to compress the layers of prepreg and reduce air pockets and remove any excess resin.

Prepregs require a combination of heat and pressure for curing. The elevated temperature causes the impregnated resin to transform the pregpreg into a solid structural material that is highly durable, temperature resistant, exceptionally stiff and extremely lightweight. This can be achieved with achieved using an autoclave, industrial oven or heated press.

- To cure a prepreg it undergoes a curing cycle. This consists of a ramp up and ramp down process in which the temperate is increased/decreased in time and degree intervals until the target temperature is met. Once the target temperature is attained, that temperature will be maintained for a determined period of time. After the ramp down, allow the part cool to room temperature, remove the vacuum bagging materials and release the part from the mold. Your part should be fully cured.

Shop Prepregs

-

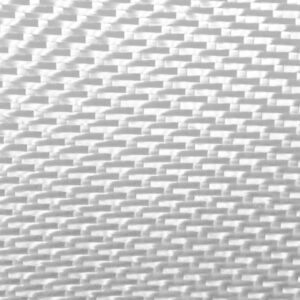

8.8oz Fiberglass RTS Prepreg – 8HS

$53.89 – $2,021.00Price range: $53.89 through $2,021.00 Select options This product has multiple variants. The options may be chosen on the product page -

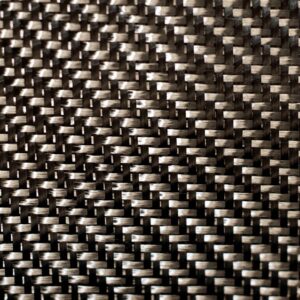

5.8 oz. Carbon Fiber RTS Prepreg – 2×2 Twill Weave

$122.00 – $4,436.50Price range: $122.00 through $4,436.50 Select options This product has multiple variants. The options may be chosen on the product page