The Do’s and Don’ts of Cutting Composites Rods and Tubes

Cutting composite rods and tubes can be easy by simply following the Do’s and Don’ts of Cutting Composite Rods and Tubes. By choosing the proper cutting blade and implement, prepping before cutting and following safety procedures for each cutting method, anyone can make accurate, clean, professional cuts to any composite rod or tube. Learn about the common cutting instruments: Tile Saw, Rotary Cutter, and Hand Cutter.

SAFETY GEAR & SUPPLIES

When cutting any type of composites, it is important to wear protective gear to prevent inhalation, ingestion, or direct exposure to cut materials. Make sure to have a face mask, protective eye wear, and gloves accessible and work in a well-ventilated area. The necessary cutting supplies include:

- Tape Measure

- Masking Tape

- Writing Implement

- Cutting Tool

- Fine Grit Sanding block

- Clamp(s) optional

CHOOSING THE RIGHT BLADE

There is a wide variety of cutting implements available on the market today. When cutting composite materials, it is best to use a cutting instrument that does not have teeth. Blade options include the following.

- A diamond or carbide coated toothless blade provides a smooth clean cut, minimal splintering and less material loss than with the use of a toothed blade. The variety of thicknesses and surface coatings make this blade ideal for cutting composite rods and tubes used in either a wet or dry saw.

- An abrasive cut off wheel is suited for many applications and is commonly recommended for use with a Dremel tool. This blades’ abrasive surface will quickly and smoothly cut composite rods and tubes.

- The Tungsten Rod is a thin, tough, alloy steel wire coated with carbide grit. It can be used in a 10″ coping saw or hacksaw to cut composite rods and tubes easily by hand.

- The Tungsten Carbide Saber Saw blade uses thousands of tiny tungsten carbide particles bonded to the cutting surface to obtain a superior cutting edge that will easily cut composite rods and tubes. When choosing a saber saw or other toothed blade, be sure to choose a fine toothed blade with at least 32 teeth per inch.

PREPPING FOR CUTTING

To prep the rod or tube for cutting:

- Measure the desired length

- Wrap the masking tape around the cut area

- Using the writing implement, re-measure and mark the cut location allowing for saw kerf which is the width of the cut.

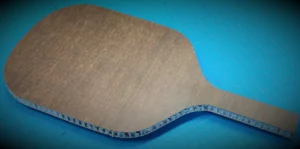

Wrapping the cut area with masking tape minimalizes splintering during cutting and produces a cleaner final cut.

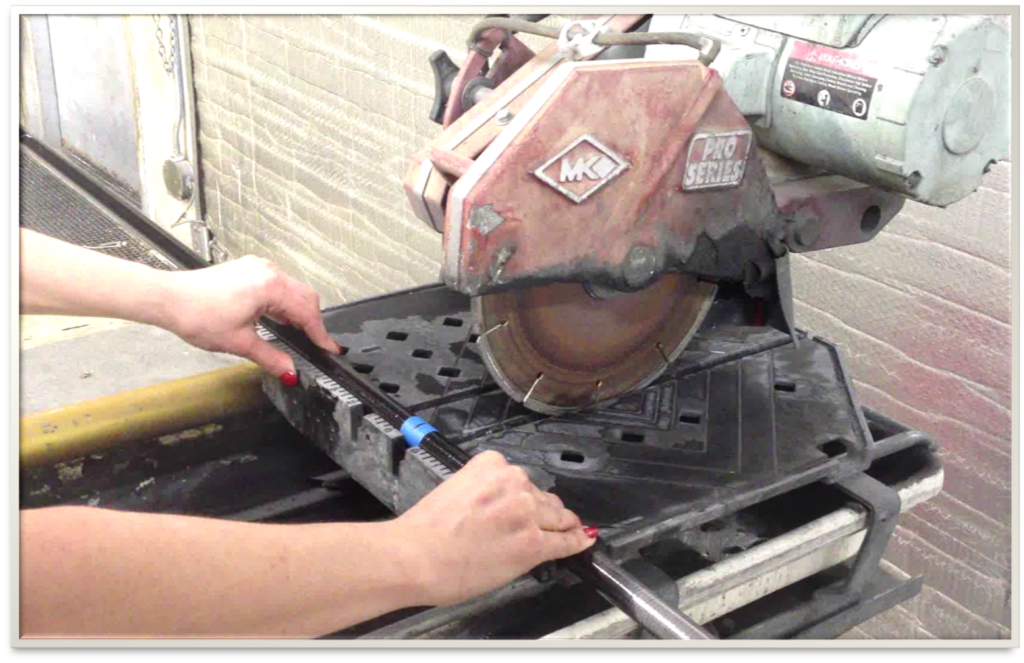

CUTTING WITH A TILE SAW WITH A TOOTHLESS CARBIDE BLADE

A tile saw is an ideal tool for cutting multiple rods and tubes or thicker materials.

Make sure that the tile saw is secured to a stable surface when cutting. Follow all proper safety precautions, keep hands free from the cutting area and wear proper eye protection.

- Ideal For | Multiple Rods and Tubes, Thicker Materials

- Benefits | Quick, clean cutting with minimal dust and splintering

- Do’s | Follow Safety Precautions

- Don’ts | Do not use a toothed blade

CUTTING WITH MACHINE POWERED HAND HELD TOOLS

Rotary Tools and Saber Saws are compact, convenient and easy to handle tools for quick, smooth cuts.

Before cutting, clamp the rod securely to a stable surface to prevent the rod from moving. Place a damp paper towel under the cutting area to catch the fibers and to make clean up easier.

Hold the tool so that the blade is perpendicular to the rod. Score the outside of the rod, cutting through the tape, and rotate as you cut. This helps to prevent uneven cuts. Burrs on the final cut can be cleaned up with a fine grit sanding block.

- Tools | Rotary Tool with an abrasive cut off whee, Saber Saw with a fine toothed Tungsten Carbide Blade

- Benefits | Quick, Smooth Cuts

- Do’s | Rotate the rod as you cut

- Don’ts | Do not cut upward

CUTTING WITH HAND HELD TOOLS

When cutting with hand tools, it is important to have the right blade. ACP Composites offers a tungsten carbide rod saw that works with a 10” coping saw or hacksaw.

Before cutting, clamp the rod securely to a stable surface to prevent the rod from moving. Place a damp paper towel under the cutting area to catch the fibers and to make clean up easier.

Score the outside of the rod and rotate as you cut. After scoring, continue to cut and rotate, being sure to cut through the center fibers last. This helps to prevent splinters and uneven cuts. Burrs on the final cut can be cleaned up with a fine grit sanding block.

- Tools | Coping Saw, Hacksaw

- Benefits | Quick, Smooth Cuts

- Do’s | Rotate the rod as you cut

- Don’ts | Do not cut upward